Every step of food production leaves something behind. Enwise saw that asuntapped potential. By converting organic by-products from food processing into energy, we are helping reimagine how resources flow through the system—reducing waste and returning power back into the loop. As member of the PepsiCo Greenhouse Accelerator APAC Program cohorts, the team explored how their solution could be applied beyond China—adapting their tech to local realities and testing its viability in new settings.

On September 10th, 2025, PepsiCo, one of the world’s leading food and beverage companies, inaugurated a green power station at its Lays factory in Lamphun, Thailand. This green power station is PepsiCo’s 2nd green power station powered by Enwise, following its first green power station at Lays factory in Wuhan, China in 2022.

These efforts are part PepsiCo Positive (PEP+) strategy to achieve a 50% reduction in combined Scope 1 and 2 emissions by 2030 against a 2022 baseline. Waste reduction is also a strategic imperative, which includes aims for increasing the use of recycled content and achieving a 99% diversion rate from landfills in its direct manufacturing and warehouse operations by 2025.

This onsite green power station marks a new step forward in PepsiCo’s commitment in use of renewable green energy as well as waste management in PepsiCo’s facilities.

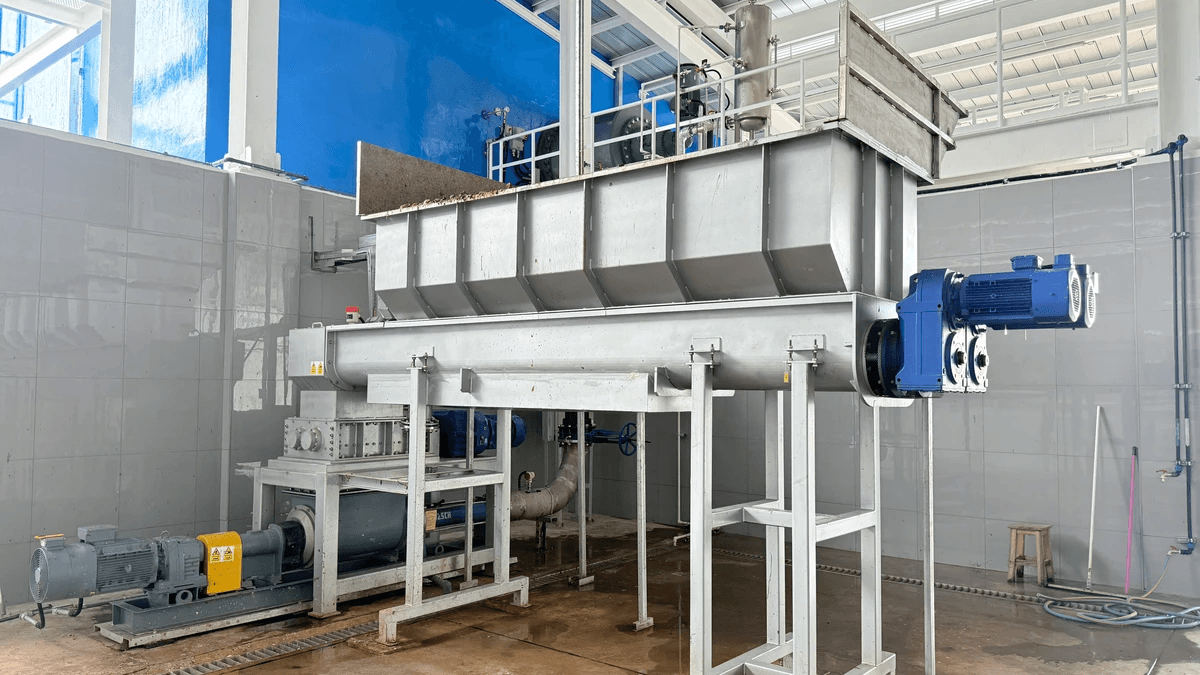

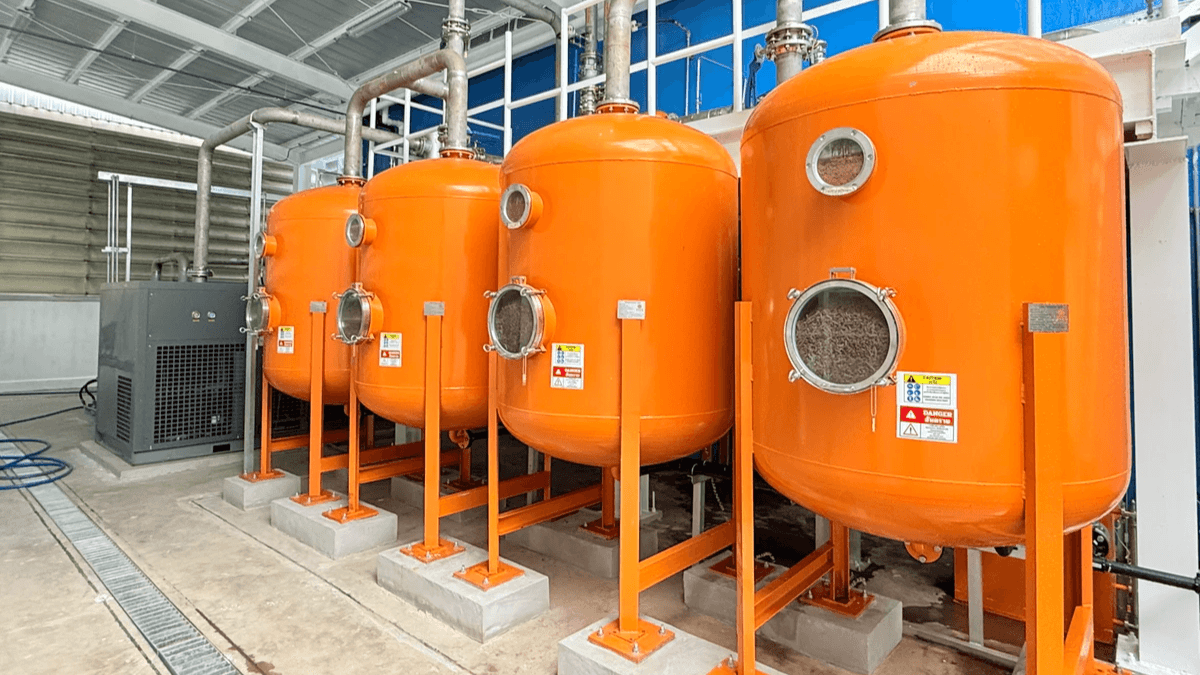

The green power station efficiently upcycles 55 tons of daily organic waste, including sludge from the factory's wastewater treatment plant, as well as potato byproducts from production line. With Enwise technology, the system converts this waste into 7,500 cubic meters of biogas per day. The biogas

generated from digester is then used to preheat the thermal oil of the production lines, covering up to 30% of the factory energy needs with sustainable fuel.

"It was extremely inspiring to see how sustainability is owned at the top management of PepsiCo and how all the levels of the organization are empowered to make an impact.” said Stephane Vernede, the CEO of Enwise,” It was also a great pleasure to work with PepsiCo Lamphun team. They are laser-focused on delivering results.”

A big thanks to PepsiCo Lamphun factory team: Kaewsom Chompunut, Daengjai Chorthip, Phetcharat Chatchai, Sanjai Anuwat, Puaktong Suwit, Pongmanee Agkapon, Sittikhankaew Jetsada, Chandee Anuwat, and Thipmala Kitti. Their continuous support was the key to deliver the project smoothly and efficiently.

Last but not least, the great work delivered from Enwise team, Zhuoya Li, Vango Gao, Zhao Jingda, Zhao Lianjun, Song Shujun, Jipeng Wang, Chris Zhang, Yingting Luo to make the vision to reality. We understand how critical fuel is to a zero-carbon food industry, and we are there as to be a building block to power a green oil and fuel industry in the future.