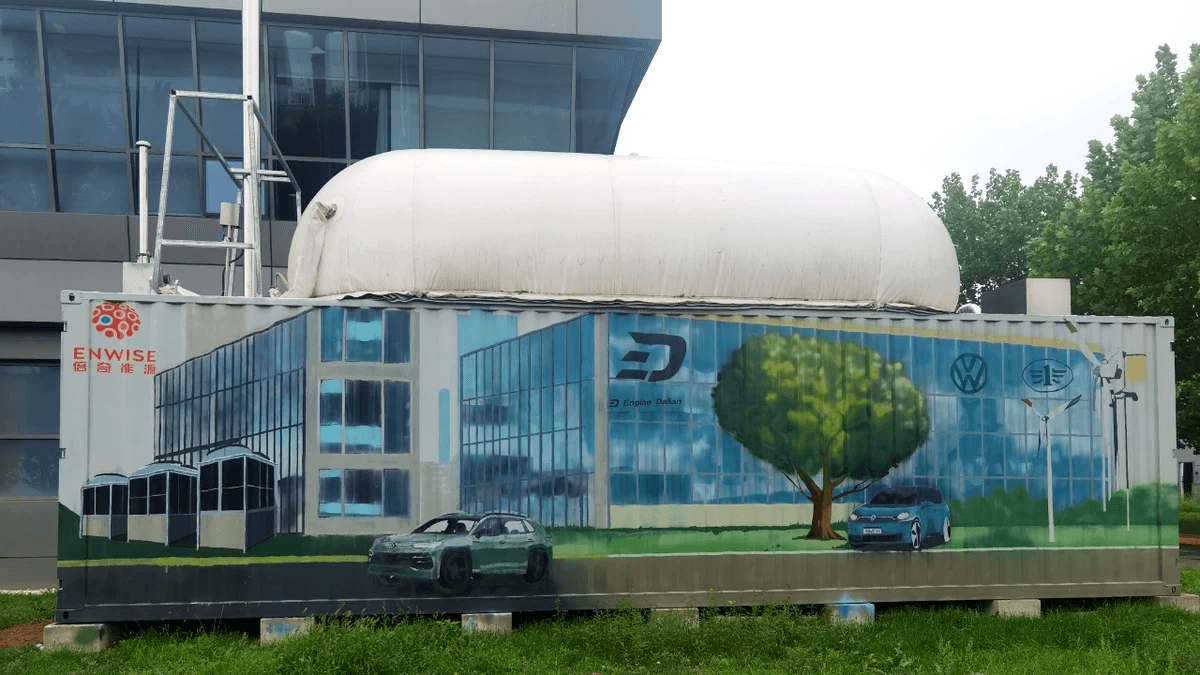

Enwise recently delivered containerized green power station at Volkswagen Dalian factory to process its kitchen waste through Enwise dry anaerobic digestion technology.

The equipment is installed next to the current food waste offloading dock, next to the employee's canteen, which imposes a minimum modification of existing workflow for kitchen workers and allows short piping for gas connection. The daily waste production at the canteen is an average of 600kg/day and peak at 1000 kg/day.

Enwise selected an Oscar model M45 unit, with processing capacity at 1000 kg/day. The Oscar is provided in two customized containers. The gas storage is provided on the roof of the digestion vessel. We

- The current digester module isdesigned to process 1000 kg/day of food waste with possibility to extend to 3000 kg/day by adding extra digesters in the future project.

- The technical module has taken the future biogas processing capacity into consideration, it is able to process 3000 kg/day of food waste input with current design.

The dry anaerobic digestor process includes:

- A shredding of the waste to amaximum size of 50mm without any water addition.

- A thermophilic dry anaerobic phase with a 30 to 40 days retention time.

- A gas holder at 20m3 to store temporarily the biogas generated from digestor.

- A biogas purification unit with dewatering and desulfuration process.

- A post-treatment of digestate with phase separation and fast composting unit.

With the implementation of Enwise green power station on-site, Volkswagen Dalian factory is able to upcycle all kitchen waste from one of their employee's canteen into bioenergy. The max biogas output of the system is able to produce 2.1 ton of hot water at 60 degrees per hour, and send to the employee back kitchen.

Enwise is very honored to run the green power station for Volkswagen and looking forward to our expanding project with Volkswagen team.