LATEST NEWS

Stay tuned with ENWISE

Searching for sustainability

As the world works to hit increasingly tough climate targets by the endof the decade, the need for sustainability in all business practices has never been greater. That, of course, includes China – from where Juliet also speaks to Stéphane Vernède, CEO & Co-founder of Enwise, an award-winning Chinese tech start up helping in the race to net-zero by converting organic waste into clean energy.

Enwise selected as the East Asia Climate Tech 100

Enwise has been selected as part of the 2022 East Asia Climate Tech 100, an annual list of the most promising Climate Tech startups from East Asia, including China, Japan, Korea & Taiwan. Startups like Enwise, now is playing a critical role of a global movement to deliver innovation across the Climate Tech landscape, building toward a more inclusive and sustainable future.

Enwise project with China State Grid

The State Grid Zhejiang Lishui Jinyun Shuiguang Hydrogen demonstration project was put into operation. This project is the first rural ecological hydrogen energy demonstration project in China. Enwise provided the digestion module for a power to gas project. This project uses the biogas of digester produced to store clean electricity through a methanation process.

A perfect combination of hardware and software

Optimize with IoT technology

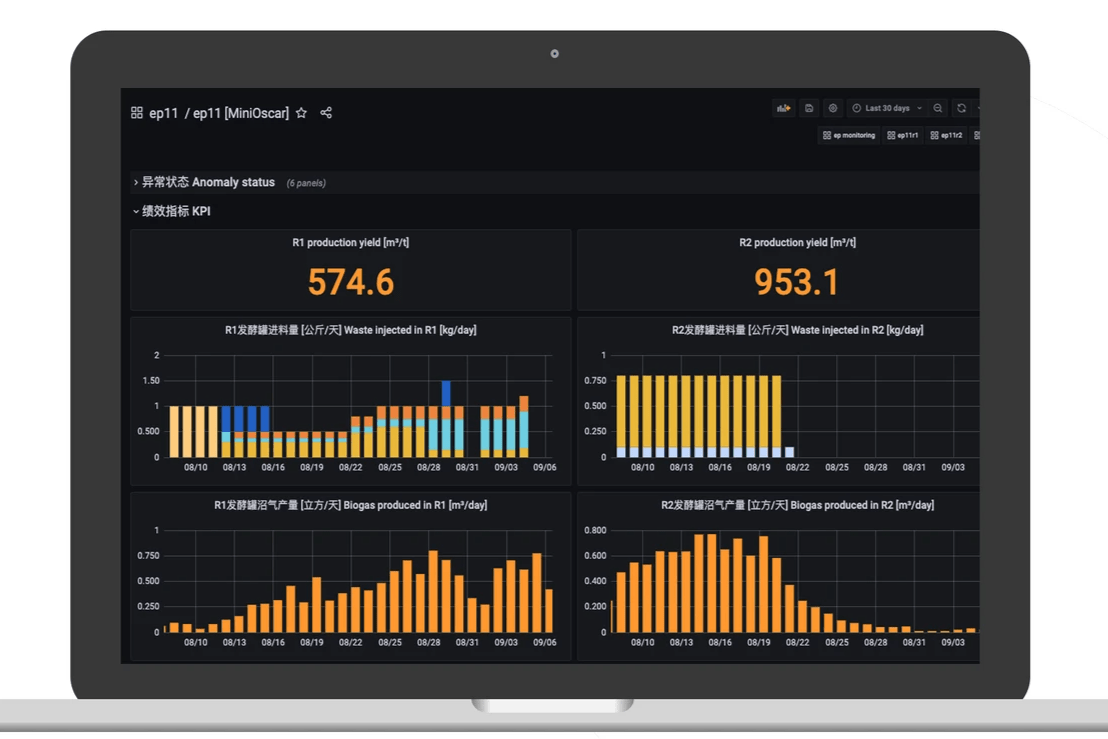

OTTO is a IoT monitoring platform that can realize 24/7 remote monitoring. The customers have access to real-time energy output, daily processing capacity, conversion rate and other core KPI performance analysis. With accumulated operation data, OTTO continuously optimizes its system performance. The IoT technical support and optimization allows remote services across continents.

REFERENCES

PEPSICO LAY'S

FOOD INDUSTRY / SLUGDES AND ORGNIAC BYPRODUCTS

Wuhan, China

The PepsiCo Lay's potato chip factory located in Wuhan, China produces a huge amount of organic waste such as waste potatoes, sludge, potato peels, and kitchen waste. The waste sent into Enwise dry anaerobic digesters then turns into renewable green electricity, which can replace over 20% of plant electricity consumption. At the meantime, the valorisation of organic waste on-site saves directly customer's initial waste disposal cost.

CHINA STATE GRID

SMART CITY / RICE STRAW, DUCK MANURE AND KITCHEN WASTE

Jinyun, China

Jinyun County, where the project is located, has lots of biomass resources, and is known as the "Hometown of Rice Seeds" and "Hometown of Hemp Ducks" in China. A large amount of discarded rice straw, duck manure and kitchen waste generated by the catering in the country house are converted into biogas through the dry anaerobic digestion technology of Enwise. Biogas is purified into green natural gas through the methanation process, and the stored natural gas can be used as civil gas, industrial fuel and other energy uses.

OATLY

SMART CITY / RICE STRAW, DUCK MANURE AND KITCHEN WASTE

Shanghai, China

Oatly's oat milk production plant in Ma'anshan, China produces organic waste such as oat residue and sludge, which can be converted into clean and renewable biomethane or renewable steam through Enwise technology. Enwise helps customers test the methane gas production potential of oat residue and organic sludge, and contributes to the customer's goal of building a sustainable factory.

DOHLER

FOOD FACTORY / SPENT GRAINS AND OAT RESIDUE

Shanghai, China

A German beverage manufacturer's factory production line in Jinshan, Shanghai produces organic waste such as oat residue and spent grains, which is converted into renewable energy-steam through Enwise dry AD technology. The company has clear ESG and carbon reduction goals. Enwise provides full-process customization energy solutions, turning waste into assets.

SUEZ

SMART CITY / FOOD WASTE

Lyon, France

Cities are facing increasing pressure of organic waste growth. To overcome these challenges, the DECISIVE smart city project deployed a container size dry anaerobic digester using ENWISE technology in Lyon, France, to pilot this innovative distributed solution for organic waste processing.

The project has been funded by the EU's Horizon 2020 Research and Innovation Programme under Grant Agreement No. 689229.

Enwise appreciates all the partners in this project for making it a reality.

For more information about the DECISIVE project please visit: https://www.DECISIVE2020.eu, video production: produced by Megapix'Ailes

INTEL

SMART CITY / FOOD WASTE

Shanghai, China

The central kitchen of this world leading computer chip manufacturing company generates around 260 tons per year of food waste and kitchen waste. These food wastes are shredded and sent into Enwise container sized dry anaerobic digester, then convert into renewable biogas, the clean fuel can be use as energy supply for cooking stoves.

AUCHAN

SMART CITY / FOOD WASTE

Shanghai, China

The fresh food counters of large supermarkets generates supermarket waste such as rotten fruits, vegetables and meats after opening every day. These wastes require the operation team to invest a lot of manpower and financial resources to clear, transport and disposal. With Enwise, Auchan supermarket realized their supermarket waste into hot water. The hot water is provided to the bathhouse of its own staff dormitory.

Take a look inside

Mail:

sales@enwise.io

Tel:

+86 182 1745 7847

+86 133 8171 6666

Address:

Room 602,Building B, No.695, Huilong Road, Qingpu district, Shanghai,PRC

© 2026 ENWISE All rights Reserved.